An Optimized Well Design for Ultradeep Carbonate Formation Drilling

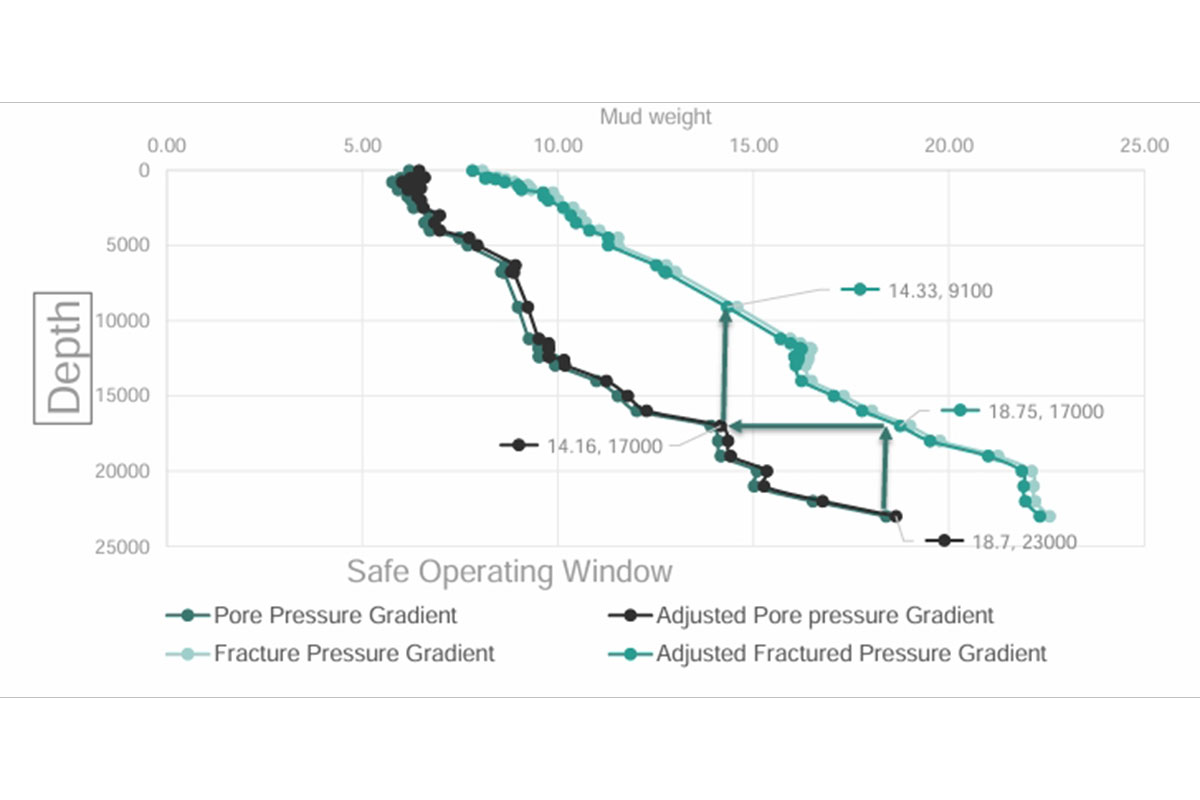

The current project designs an extensive well drilling system to penetrate a complex carbonate reservoir at its total depth of 23000 feet. A detailed design approach delivers reservoir pressure profiling together with optimal mud selection and proper casing design and cementation scenarios alongside bit selection to endure standard ultradeep HPHT situations. Carbonate reservoir drilling proves difficult due to its mixed nature which includes multiple formations of fractures together with vugs and irregular pressure gradients. The study implements an in-depth investigation of subsurface pressures to choose suitable drilling fluids and proper drilling equipment in combination with correct casing grades. The proposed methodology uses theoretical calculations together with industry standards together with advanced drilling technologies MWD and LWD for real-time data acquisition and monitoring. The contemporary equipment systems give vital formation traits data to enhance drilling efficiency and reduce problems caused by formation damage and lost circulation and wellbore instability. The drilling operation receives special focus regarding environmental considerations as well as economic aspects. The process of cost optimization includes selecting appropriate casing materials and bit types in order to fulfill both operational requirements and financial limitations. The established design achieves an ideal combination between operational safety and efficiency and environmental sustainability and economic effectiveness to establish a reliable drilling foundation in ultradeep carbonate strata.

Project Details

- Student(s): Batoul J. Moughraby, Ibrahim Ghannam, Rimi A. Charafeddine

- Advisor(s): Dr. Zisis Vryzas

- Year: 2024-2025

![[photo]](https://soe.lau.edu.lb/images/capstone_ece_24-25_optomizedWellDesign_pic2.jpg)