Ultrasonic assisted machining of brittle material

Project Details

- Student(s): Elie Bachir

- Advisor(s): Dr. Roland Bejjani

- Department: Industrial & Mechanical

- Academic Year(s): 2021-2022

Abstract

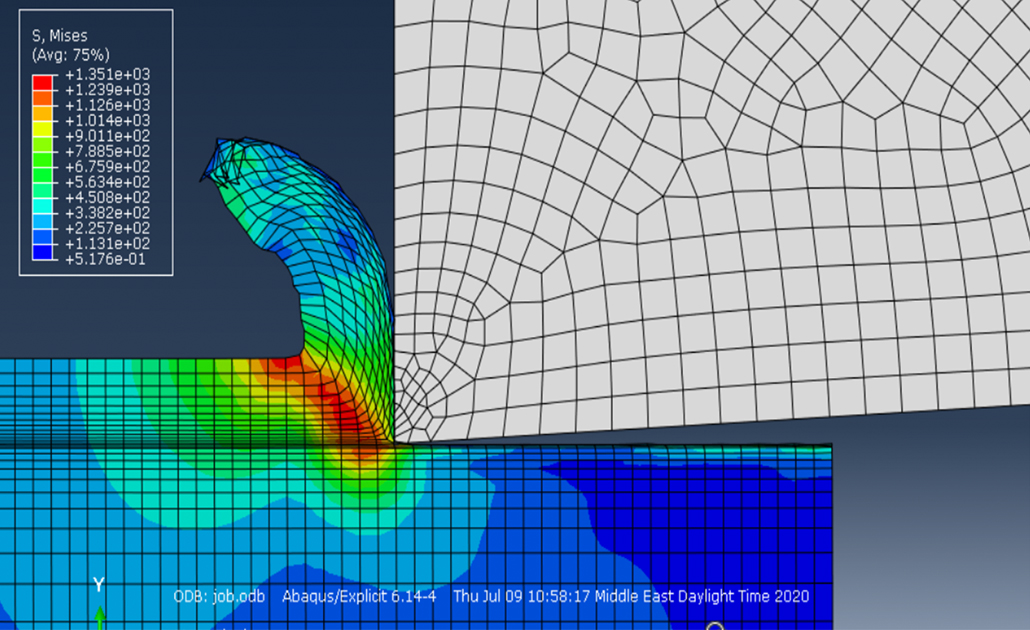

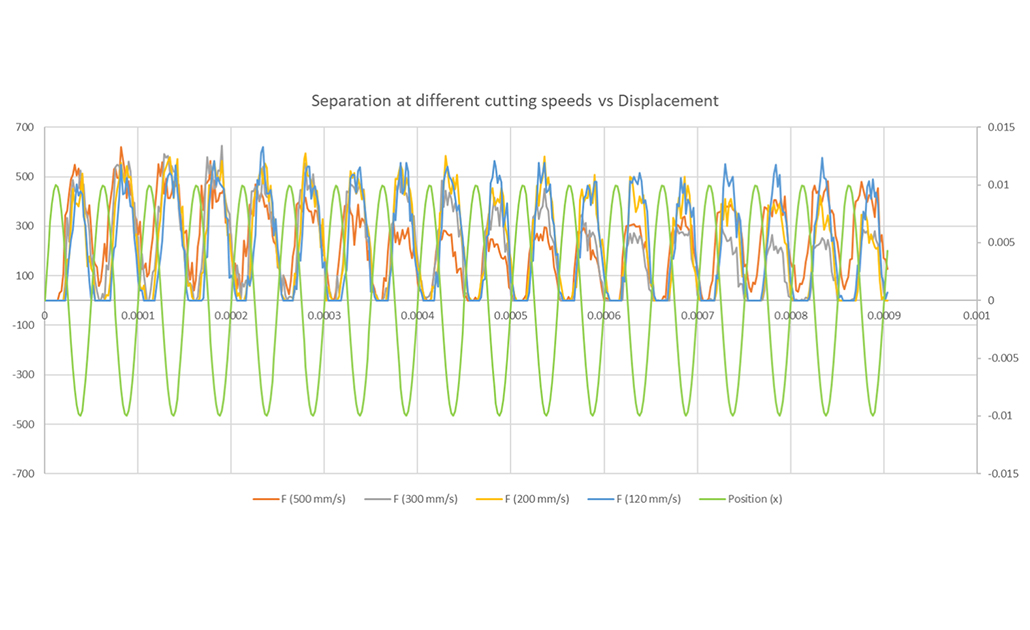

Machining has usually been preserved for ductile material such as steel since it is less hard compared to ceramics and other brittle material. The forces induced in machining are damaging for the cutting tool which also needs to be harder than the material being machined. A new technology that has been shown to reduce the cutting forces and improve the surface finish “Ultrasonic Assisted Turning” which consists of vibrating the tool used for turning with an ultrasonic frequency. The design of an Ultrasonic Device will enable new possibilities in manufacturing. Piezoelectric ceramic will allow the vibration of the tool holder controlled by a generator in an electric circuit. This device can easily be installed into a turning lathe. The results are expected to enable machining many advanced and brittle materials. This work is expected to benefit the manufacturing of brittle materials such as piezoelectric ceramics and glass. Furthermore, the surface generated by such a method can enable the surface texturing of the finished part, which can be required by microfabrication.

Publications:

- Bachir E., Bejjani R. An experimental and FEM study on ultrasonic-assisted turning of titanium alloy. Journal of MACHINING SCIENCE AND TECHNOLOGY 2023. https://doi.org/10.1080/10910344.2023.2231066

- Bejjani R., Bachir E., Salame C. Advanced Manufacturing of Titanium Alloy Ti-6Al-4V by Combining Cryogenic Machining and Ultrasonic-Assisted Turning’. Journal of Materials Engineering and Performance, ASM, June 2023