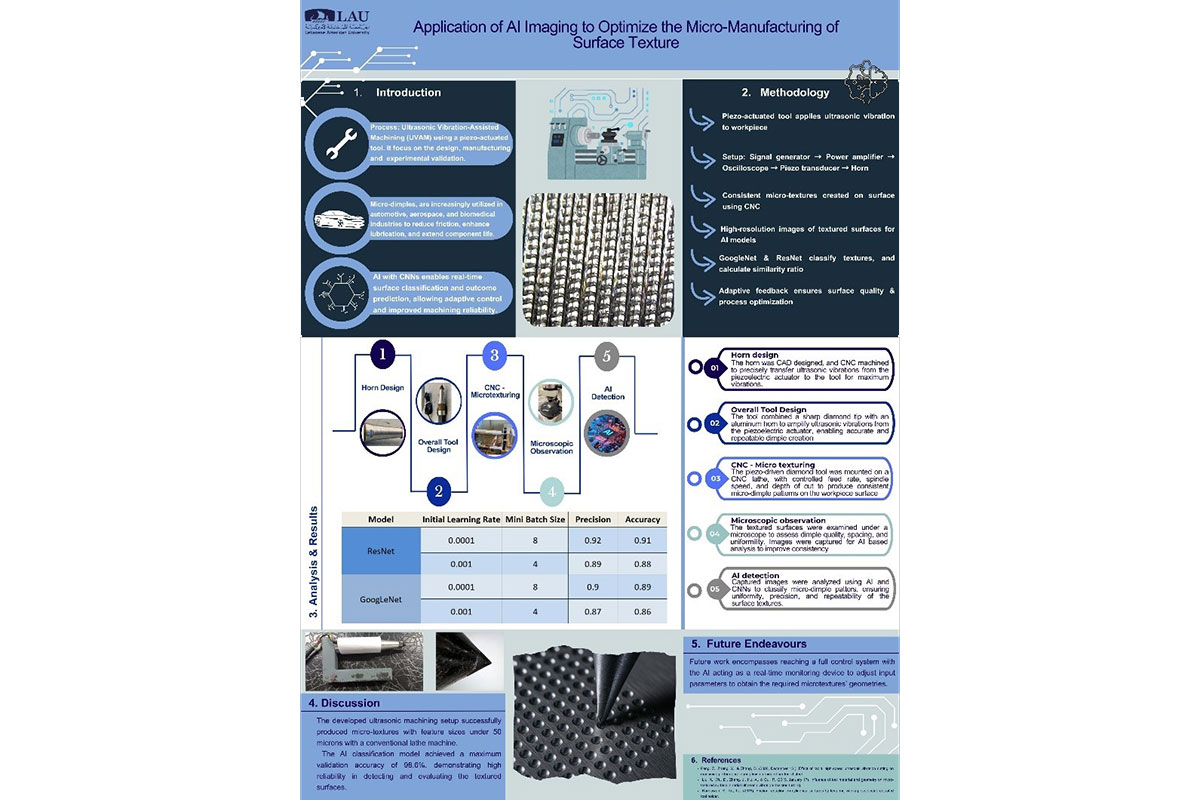

Application of AI imaging to optimize the Micro-Manufacturing of Surface Texture

Project Details

- Student(s): Cynthia Al Labaki

- Advisor(s): Dr. Roland Bejjani

- Department: Industrial & Mechanical

- Academic Year(s): 2024-2025

Abstract

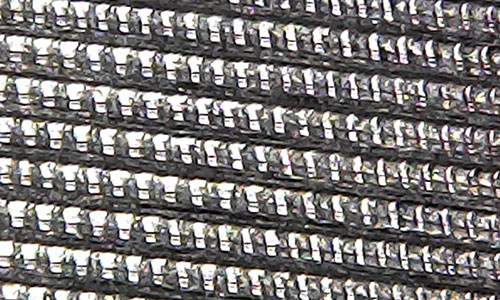

With the increasing demand for micro-scale precision in industries such as aerospace, semiconductors, and sensors, advanced manufacturing techniques have become essential. This work involved the creation of micro-structures using both femtosecond laser machining and ultrasonic vibration-assisted turning. In the ultrasonic turning process, various machining and electrical parameters were adjusted to optimize the formation of consistent, high-quality dimples. For both techniques, Convolutional Neural Networks (CNNs), including GoogleNet and ResNet50, were used to classify the resulting surface features. The models were evaluated based on validation accuracy, precision, recall, F1-score, and repeatability ratio. ResNet demonstrated greater consistency with round geometries, while GoogleNet performed better with sharp-edged patterns. This integrated approach—combining experimental parameter tuning and AI-based classification—provides a reliable and repeatable method for micro-texture evaluation and quality control in precision manufacturing.