Case Study of Lean in Hospital Admissions to Inspire Culture Change

Project Details

- Student(s): Joseph Salem and Rami Otayek

- Advisor(s): Dr. Marc Haddad and Dr. Pierrette Zouein

- Department: Industrial & Mechanical

- Academic Year(s): 2015-2016

Abstract

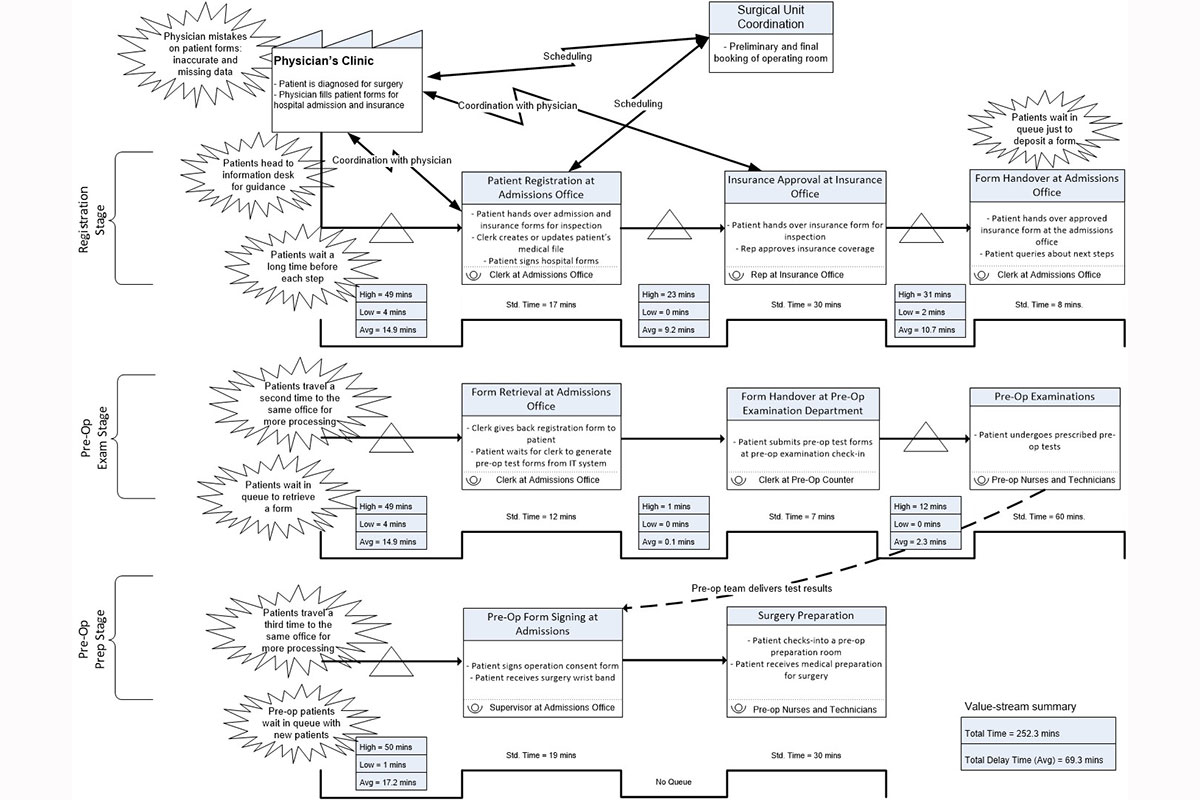

The hospital admissions process is a distinct experience for patients as this is where they start their journey for medical care, usually with a mix of anxiety and anticipation about what is to follow. This process also happens to be long and stressful, with numerous steps, frequent delays, and the occasional glitches along the way. In this study, we used lean thinking and discrete-event simulation to map and model the inpatient admissions process at a multi-specialty hospital in order to improve patient flow and reduce unnecessary waiting and handling by patients and staff. We found that by applying a combination of simple but complementary lean techniques, it was possible to reduce the total patient time in the system by up to 43%, without incurring additional costs or using more resources. The potential for achieving substantial improvements at low cost, combined with the approach of validation-prior-to implementation adopted in this study, can both help process engineers and engineering managers to build support for any proposed lean initiative. This also makes it possible to sustain continuous improvement in the long term, which is at the heart of the lean approach.

This study focused on demonstrating how lean can be used to improve the inpatient admissions process. Our aim was to illustrate the step-by-step application of multiple lean techniques for improving a patient journey through the admission process. Unlike previous work that focused on illustrating the benefit of a single or separate techniques in addressing independent wastes, our research illustrated the application of multiple lean techniques to eliminate waste, demonstrating that a comprehensive use of lean can yield tangible benefits at a systemic level. Our results demonstrate that significant improvements to the flow of patients can be achieved using only low-cost, easy-to-implement lean techniques with no new overhead or infrastructure costs. Another contribution of this work is in providing a complete and detailed illustration of how lean thinking and simulation modeling can be used as complementary methodologies to assess and validate the effectiveness of proposed changes. The case study presented in this article provides a proof-of-concept which addresses many of the above issues.

Publication

- Haddad M., Zouein P., Salem J. and Otayek R. Case Study of Lean in Hospital Admissions to Inspire Culture Change, Engineering Management Journal, 28:4, 209-223, 2016. DOI: 10.1080/10429247.2016.1234896.