Laser Textured Cemented Carbide Tools for Dry Titanium Turning

Project Details

- Student(s): Zaky Bou Farhat and Marc Chamoun (Graduate student)

- Advisor(s): Dr. Roland Bejjani

- Department: Industrial & Mechanical

- Academic Year(s): 2024-2025

Abstract

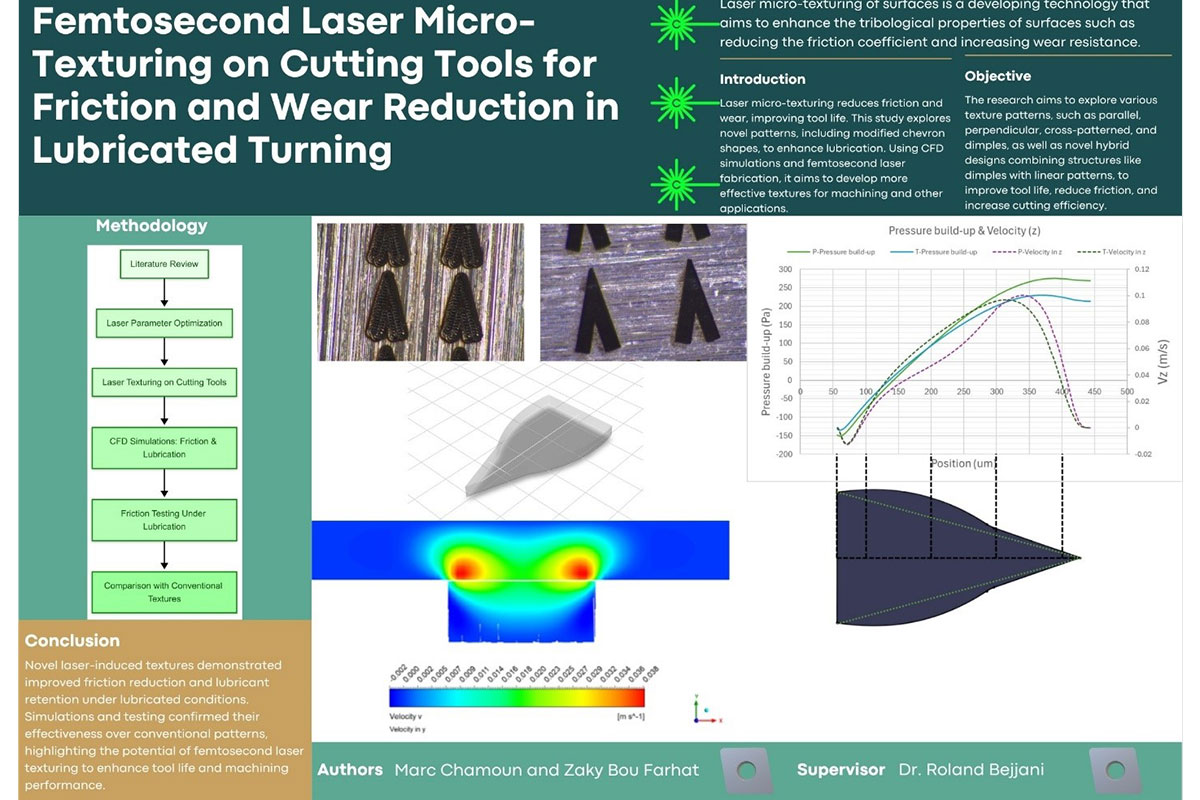

Cemented carbide tool micro-texturing using femtosecond laser ablation has been widely explored to enhance dry cutting performance for titanium alloy machining by reducing cutting forces and tool wear. This study investigates novel micro-texture patterns at a smaller scale than previously utilized, aiming for improved performance over existing designs. Moreover, the proposed textures were manufactured through optimized femtosecond laser parameters, ensuring accurate pattern formation. Then, the characterization of these textures was conducted using Scanning Electron Microscopy (SEM), Energy Dispersive Spectroscopy (EDS), and Optical Confocal Microscopy to assess their morphology and composition before and after cutting experiments. Experimental results demonstrated that the newly designed patterns significantly reduced cutting forces and effectively trapped saturated titanium, mitigating chemical wear on the tool surface. Thus, the findings highlight the potential of reducing the micro-texture scale while incorporating innovative geometries to enhance tool performance. This study contributes to the advancement of femtosecond laser texturing for cutting tools, offering a promising approach for improved machining efficiency and tool life.