Bike Chain: Dynamic Supply Chain Management and Hardware Integrated Production Tracking for Bicycle Manufacturing Automation

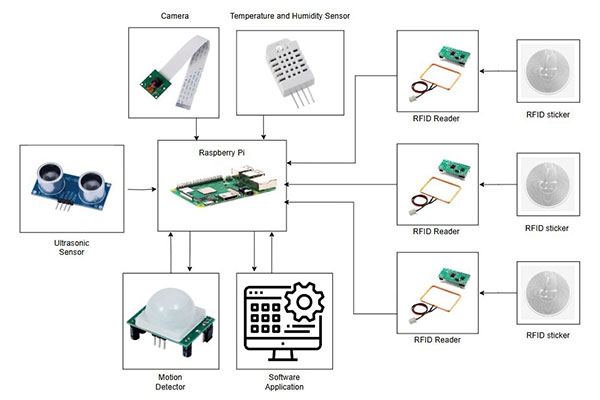

Our project is a supply chain management system for bicycle factories, addressing challenges manufacturers face due to market disruptions. To be more specific, the project optimized the manufacturing and inventory management sections of the supply chain. This was achieved by integrating advanced algorithms, hardware components and data analysis techniques. Current supply chain management models in the market lack dynamic aspects, and fail to address sudden changes in market trends, hence our work combined the benefits of agile models, ABC models, and AI forecasting models to achieve a model that can handle real market dynamic demands. For the software part of our system, we developed a user-friendly application that uses an AI forecasting model combined with an ABC model to predict manufacturing and storage levels, offers supplier selection to prioritize lead time or cost, data analytics to assess the factory’s performance, employee task tracking, and assess manufacturing and inventory capacities. For the hardware system, RFID technology was used to ensure live tracking of products being manufactured throughout the manufacturing stages and various sensors to monitor environmental conditions, product locations, and ensure safety, which can all be accessed and monitored through the software application. Our factory focuses on the production of several bike types such as road bikes, mountain bikes, hybrid bikes, and BMX. The project examined component sourcing, manufacturing production levels and integrating artificial intelligence to improve decision making. Ultimately, the proposed system streamlined inventory management, reduced unnecessary costs, and enhanced factory efficiency.

Project Details

- Student(s): Jude Soueid, Mohamad Nasser, Zakhia Tayeh

- Advisor(s): Dr. Maria Abi Saad

- Year: 2024-2025

![[photo]](https://soe.lau.edu.lb/images/capstone_ece_24-25_BikeChain_pic2.jpg)